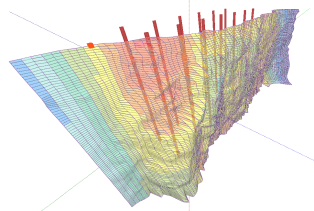

To ensure the security of the settlements, the software is able to integratre the 3D profile of fronts, whatever the type of devise used. This geometrical knowledge, once acquired, can model the implantation directly on computer : tilt, depth, orientation of the drilling, as much information as is available to the driller, so that he can work under the best conditions.

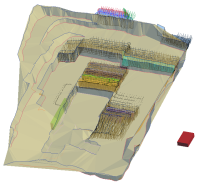

During drilling, the driller logs all anomalies of the ground tha are encountered. This drilling report is fully embedded into the 3D EXPERTIR Software, to gather all the information on the same support for the design of the fire plan.

To verify that the drilling matches the implantation, the exact hole position is taken with a precision GPS. Then each hole is checked, using an inclinometer sensor to monitor any possible deviations wich might occur during the drilling.

Once the geometric information and field data are collected in the same software, it is up to the miner to use his experience to establish the optimized fire plan.

Thus all the elements are available to establish a safe fire plan, guaranteeing optimum mass distribution, while respecting the environment by limiting the vibrations. A hole-by-hole loading plan for quality mining can be obtained in this way. All shooting plans are incorporated into a global topographic model for continuous tracking of the mining activity.

To learn more about the mining methods from EPC-France, please watch the video in the box on the top right.